8,000-10,000 pcs/h

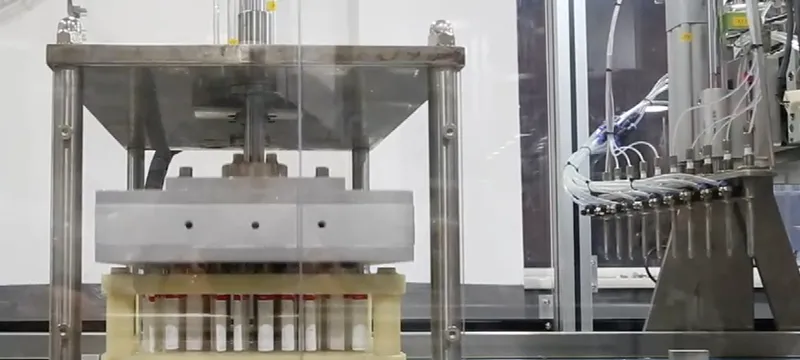

Modular Non-Vacuum Blood Collection Tube Assembly Line

Blood collection tube assembly machine for non-vacuum blood collection tubes

Finished Product Samples

With its modular design, clients can buy only some modules at the beginning stage, then add other modules gradually to upgrade it into a fully automatic line when the manufacturing plant needs to be expanded in future.

This assembly line allows manufacturers to reach a production capacity of 8,000 to 10,000 non-vacuum blood collection tubes per hour. The system is perfectly suited for the automated production of 13×75mm and 13×100mm non vacuum tubes (PP or PS).

Work Flow

- Inversion detection

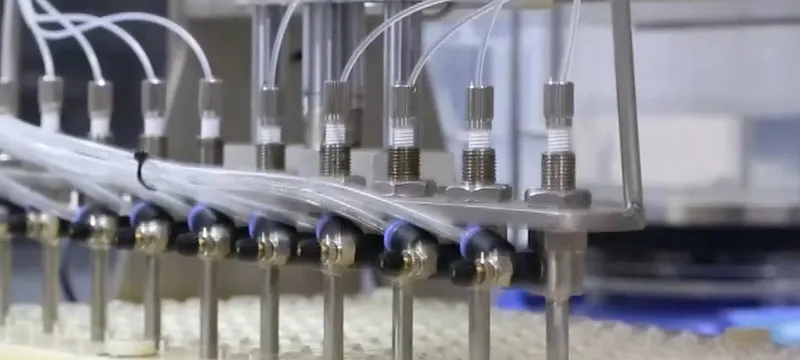

- Additive dosing (EDTA, heparin, clot activator, sodium citrate)

- Capping

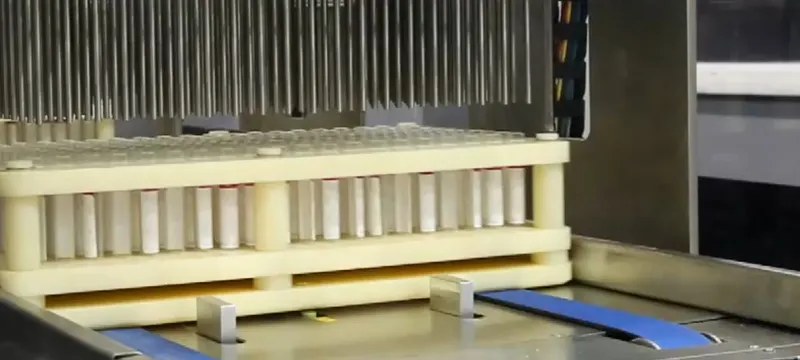

- Foam tray loading

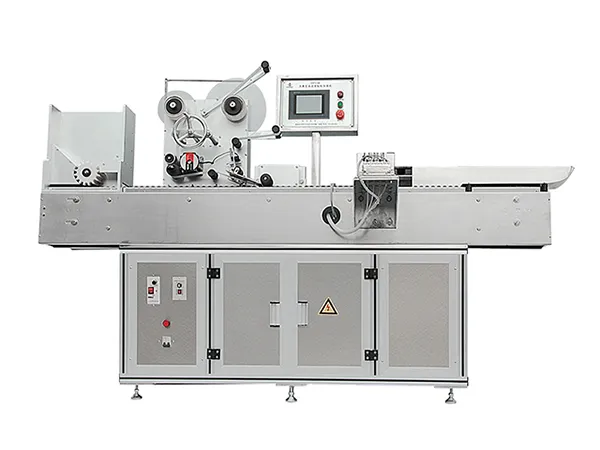

- Heat shrink packaging

- Completion

Technical Specifications

| Model | 100AM |

| Production capacity | 8,000-10,000 pcs/h |

| Tube size | Ø13×75mm, Ø13×100mm, customizable |

| Cap size | As per client’s samples |

| Control system | PLC control with touch screen |

| Additive dosing system | K2/K3 EDTA: 10 sets of precision ceramic pump |

| Blood clot activator (BCA): 10 sets of precision ceramic pump | |

| Sodium citrate: 5 sets of precision ceramic pump | |

| Additive drying system | 3 PTC dust-free drying machines |

| Detection system | Inverted tube detection before additive dosing |

| Alarm for shortage of foam trays | |

| Air consumption | Max. 1 m³/min Air supply pressure P:0.7Mpa≤P≤1Mpa |

| Power | 20kW/AC380V |

Related Products

We provide efficient assembly solutions tailored to your medical device needs

Get in Touch

About HONGREAT

Your Reliable Partner for Blood Collection Tube Assembly Solutions

- 220Partner of over 220 companies globally

- 40Exporting to more than 40 countries worldwide

- 20Over 20 years of experience in manufacturing blood collection tube assembly equipment

- 1010+ years dedicated to after-sales service

- 19Holder of 19 patents in blood collection tube machine technology